The Art of Precision

All of ISCI’s products are proudly manufactured in the USA with all domestic materials.

Award-Winning Quality and Delivery

Quality is job one for everyone at ISCI. Every level of production, product handling, packaging and shipping is carefully monitored by a seasoned quality control department.

In an industry where quality is “precision,” there are no shortcuts, and in our organization there are no “small” jobs. Each and every part we ship is critical to the success of our customers, so we go the distance in meeting or exceeding client specifications for precision.

ISCI also offers another option for our customers which involves finishing on machined parts. In addition to our anodizing facility we also offer on-site military spec painting. Our state of the art painting facility offers a clean and efficient solution for any prospective client interested

in military spec painting.

Personnel in this division of ISCI are experienced in the intricate processes in preparing and painting the highest quality part. The process begins with a thorough investigation of the parts received to insure the most accurate painting possible. Documentation on qualifications and

certification of paint are also kept up with stringently by this division of ISCI, with emphasis placed on timely updates from the field.

ISCI’s anodizing division provides full-service, high-quality processes, and specializes in small parts and system components. Our proprietary racking systems are designed for high density racking and unracking, generating customer savings from maximum efficiency.

Personnel in this division are experienced in applying the appropriate measures for handling delicate parts and controlling the variables involved in surface conversion throughout processing. Beginning with a thorough evaluation of parts received, through written documentation of the process at every level, our anodizing team is focused on two priorities: quality and prompt delivery.

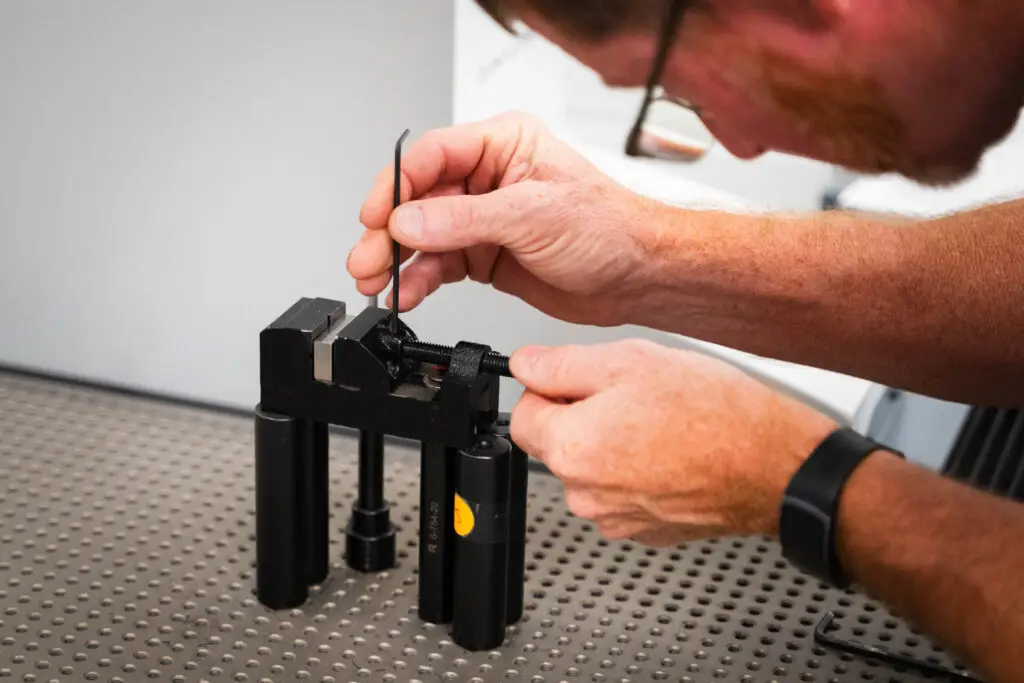

We don’t just machine parts and assemblies – we build machines and tooling as well! ISCI’s Manufacturing Facility provides clients with real world solutions, from print to completion.

The guiding principle and heart of our manufacturing services is client interaction. We take the time to understand what the client requires. Then, through a mix of project review and applied technology, we are able to deliver parts, assemblies and equipment that are efficient, realistic, delivered on time and within budget.

The centerpiece of our documentation system is industry-recognize ERP software networked throughout our operation. The system tracks and provides real-time information on all orders including the initial quoting process, material purchasing, manufacturing, inspection, shipping and billing.

ISCI creates precision machined parts and assemblies that require exacting fit, form and finish for companies around the world.

Our machine shop area is operated for maximum accuracy and total set-up and programming efficiency. Working areas are clean, quiet and climate controlled – providing an atmosphere conducive to the production of intricate precision parts. Our complete precision machine shop division is well-equipped, including conventional machining and the latest CNC machining capabilities.